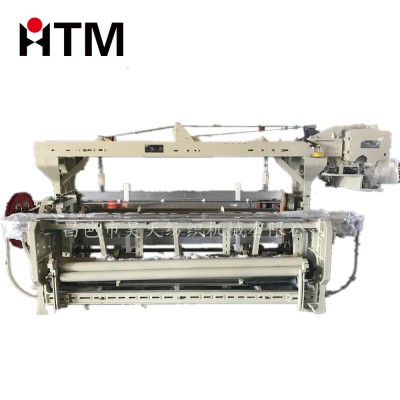

商品描述

GA798挠性剑杆织机以棉纤维、天然纤维、人造纤维以及装饰丝(比如棉、聚酯、蚕丝、羊毛、丙烯酸、人造丝、尼龙和花式纱线)等为原料,主要用于织造20-800克/sqm轻重不一的素缎面料,有装饰布,纱窗料、花布、亚麻布、棉布、化纤布,西装及衬衫面料等。另外,我们实现了变纬密织造,纬密可控范围5~46纬/cm。

运行稳定,维修保养简易,低噪音,外观优雅,人性化的控制和操作系统,电机反应迅速,工作持久,能耗低,良好的综合性能确保了系统安全稳定。

主要技术参数

1.筘幅宽度

150,180, 200, 230, 280, 330(cm).

2.转 速

设计速度160~250rpm.

3. 入 纬 率

每分钟160-180米通过左右剑带和剑头

4. 经轴直径

标准600mm.

5. 卷布轴直径

300mm,可匹配大卷取机构

6.储 纬 器

FDP电子储纬

7.驱动控制

额定主电机功率0.8~1.3kw,3相电,380v,50hz,电磁离合器制动。

8. 打纬机构

曲轴引纬打纬

9. 润滑系统

油泵,多臂自动加油。

10. 电路设计

采用标准模块化设计,LED发光管显示工作状态,易检修,使用成本低。

11. 选纬机构

机械多臂牵引4-6色选纬机构。

12. 织造范围

细纱:500tex (1.2Ne)~5tex (120Ne);长丝纱线:10dte(9td )~1650dte(1500Td).

13. 开口方式

8-12片综框,机械多臂最多20轴自动开口,可匹配大提花机。

14. 送经机构

储纬器连杆联动控制半积极送经系统,反应灵敏,张力稳定。

15. 卷取机构

连续无间隙卷曲,可设定每一纬纬密,且支持同步变纬密织造。

16. 布边形成

机械边剪,纱罗布边;伸幅装置:单排铜刺环辊式。

17. 停车装置

停经:单独电动停经;停纬:高灵敏度压电探测器自动停止。4色多功能指示灯显示停车状态。

18. 电子控制

微电脑多功能自动控制系统附带存储卡,按钮操作,方便简单,即时调整。

19.尺寸/重量

450*250*260cm3, 1.8~2.0 MTs.

GA798 flexible rapier loom with cotton fiber, natural fiber, synthetic fiber and decorative silk (such as cotton, polyester, silk, wool, acrylic acid, rayon, nylon and fancy yarn) as raw materials, mainly for weaving 20-800 grams /sqm severity of satin fabric, decorative cloth, screen window material, cloth, linen, cotton cloth, chemical fiber cloth suit and shirt fabric and so on. In addition, we have realized the change of weft density, weft density and controllable range 5~46 weft /cm.

Stable operation, easy maintenance, low noise, elegant appearance, user-friendly control and operation system, high-quality motor response quickly, work for a long time, low energy consumption, good comprehensive performance to ensure that the security and stability of the system.

Main technical parameters

1 reed width

150180, 200, 230, 280, 330 (CM).

2 rpm

Design speed 160~250rpm.

3 weft insertion rate

160-180 meters per minute through the left and right side of the sword and the sword

4 beam diameter

Standard 600mm.

5 rolling shaft diameter

300mm, can take large matching mechanism

6 weft storage device

FDP electronic weft storage

7 drive control

Rated main motor power 0.8~1.3kw, 3 phase power, 380V, 50Hz, electromagnetic clutch brake.

8 beat up mechanism

Crankshaft weft insertion

9 lubrication system

Oil pump, multi arm automatic refueling.

10 circuit design

Using standard modular design, LED LED display working status, easy maintenance, the use of low cost.

11 weft selection mechanism

Mechanical multi arm traction 4-6 color weft selecting mechanism.

12 weaving range

Spinning: 500tex (1.2Ne) ~5tex (120Ne); filament yarn: 10dte (9td) ~1650dte (1500Td).

13 opening method

8-12 piece of integrated frame, mechanical multi arm up to 20 axes automatic opening, can match the big jacquard machine.

14 warp feeding mechanism

Weft rod linkage control of semi active warp feeding system, sensitive reaction and stable tension.

15 coiling mechanism

Continuous no gap curl, can be set for each weft density, and support for synchronous change weft density weaving.

16 selvage forming

Mechanical cutting edge, leno selvedge; tentering device: single row copper thorn ring roller.

17 parking device

Menopause: single electric menopause; weft stopping: high sensitivity of piezoelectric detector automatic stop. 4 color multi function indicator display parking status.

18 electronic control

Microcomputer multifunction automatic control system with memory card, button operation, convenient and simple, real-time adjustment.

19 size / weight

1.8~2.0, MTs. 450*250*260cm3

企业资料通过认证

企业资料通过认证