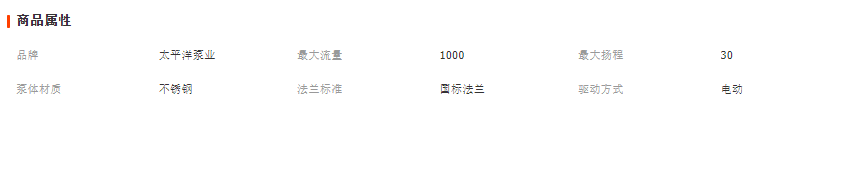

商品描述

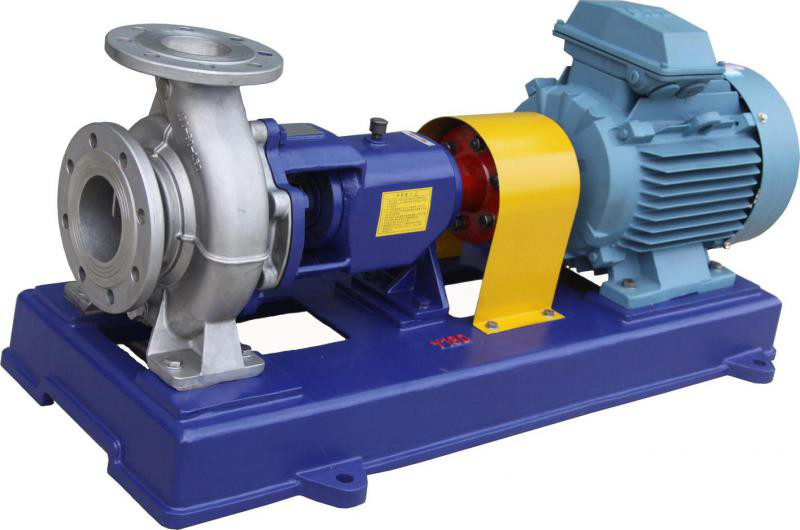

一、IH单级单吸化工离心泵产品概述

IH单级单吸化工离心泵供输送不含固体颗粒具有腐蚀性、粘度类似水的液体。其标记、额定性能和尺寸等效采用国际标准ISO2858,具有性能范围广、效率高、“三化”水平高和维修方便等特点,其效率比F型泵平均提高5%,是国家推广的节能产品。

二、IH单级单吸化工离心泵应用领域

IH单级单吸化工离心泵输送介质温度为-20℃~105℃,需要时采用冷却措施可输送更高温度的介质,适用于化工、石油、冶金、电力、造纸、食品、制药、环保、废水处理和合成纤维等行业用于输送各种腐蚀的或不允许污染的类似于水的介质。

三、IH单级单吸化工离心泵产品特点

IH单级单吸化工离心泵普及性高,性能稳定,系统工作压力≤1.6MPa,可按照用户使用条件订做不同不锈钢材质304,316、316L,CD-4Mcu,904,904L,哈氏合金等密度范围P=1.0~1.84×103kg/m3

四、IH单级单吸化工离心泵型号意义

IH50-32-160

IH - 化工离心泵

50 - 吸入口直径(mm)

32 - 排出口直径(mm)

160 - 叶轮名义直径(mm)

A - 叶轮外径经第一次切割

五、IH单级单吸化工离心泵技术参数

流量:6.3~400m3/h;

扬程:5~125m;

转速:1450、2900r/min;

功率:0.55~90kw;

进口直径:50~200mm;

出口直径:32~150mm。

六、IH单级单吸化工离心泵性能参数

IH型单级单吸化工离心泵

序号 | 型号规格 | 流量 | 扬程 (m) | 转速 (r/min) | 功率 (KW) | |

(m³/h) | (L/S) | |||||

1 | 25-20-160 | 4 | 1.1 | 32 | 2900 | 1.5 |

2 | 25-20-160A | 3.7 | 1.0 | 28 | 2900 | 1.1 |

3 | 32-25-125 | 5 | 1.4 | 20 | 2900 | 1.5 |

4 | 32-25-125A | 4.5 | 1.3 | 16 | 2900 | 1.1 |

5 | 32-25-160 | 5 | 1.4 | 32 | 2900 | 2.2 |

6 | 32-25-160A | 4.5 | 1.3 | 25 | 2900 | 1.5 |

7 | 32-25-200 | 5 | 1.4 | 50 | 2900 | 3 |

8 | 32-25-200A | 4 | 1.1 | 40 | 2900 | 2.2 |

9 | 40-25-125 | 6.3 | 1.8 | 20 | 2900 | 1.5 |

10 | 40-25-125A | 5.6 | 1.6 | 16 | 2900 | 1.1 |

11 | 40-25-160 | 6.3 | 1.8 | 32 | 2900 | 2.2 |

12 | 40-25-160A | 5.9 | 1.6 | 28 | 2900 | 1.5 |

13 | 40-25-200 | 6.3 | 1.8 | 50 | 2900 | 4 |

14 | 40-25-200A | 5.9 | 1.6 | 44 | 2900 | 3 |

15 | 40-25-250 | 6.3 | 1.8 | 80 | 2900 | 11 |

16 | 40-25-250A | 5.9 | 1.6 | 70 | 2900 | 7.5 |

17 | 40-32-125 | 7 | 1.9 | 20 | 2900 | 1.5 |

18 | 40-32-125A | 6.2 | 1.7 | 16 | 2900 | 1.1 |

19 | 40-32-160 | 7 | 1.9 | 32 | 2900 | 2.2 |

20 | 40-32-160A | 6.6 | 1.8 | 28 | 2900 | 1.5 |

21 | 40-32-200 | 7 | 1.9 | 50 | 2900 | 4 |

22 | 40-32-200A | 6.6 | 1.8 | 44 | 2900 | 3 |

23 | 50-32-125 | 12.5 | 3.5 | 20 | 2900 | 2.2 |

24 | 50-32-125 | 6.3 | 1.8 | 5 | 1450 | 0.55 |

25 | 50-32-125A | 11.3 | 3.1 | 16.4 | 2900 | 1.5 |

26 | 50-32-125A | 5.7 | 1.6 | 4.1 | 1450 | 0.55 |

27 | 50-32-160 | 12.5 | 3.5 | 32 | 2900 | 3 |

28 | 50-32-160 | 6.3 | 1.8 | 8 | 1450 | 0.55 |

29 | 50-32-160A | 11.3 | 3.1 | 26.4 | 2900 | 3 |

30 | 50-32-160A | 5.7 | 1.6 | 6.6 | 1450 | 0.55 |

31 | 50-32-160B | 10.5 | 2.9 | 22 | 2900 | 2.2 |

32 | 50-32-160B | 5.25 | 1.5 | 5.5 | 1450 | 0.55 |

33 | 50-32-200 | 12.5 | 3.5 | 50 | 2900 | 5.5 |

34 | 50-32-200 | 6.3 | 1.8 | 12.5 | 1450 | 1.1 |

35 | 50-32-200A | 11.3 | 3.1 | 41 | 2900 | 4 |

36 | 50-32-200A | 5.7 | 1.6 | 10.3 | 1450 | 0.75 |

37 | 50-32-200B | 10.5 | 2.9 | 35.5 | 2900 | 4 |

38 | 50-32-200B | 5.25 | 1.5 | 9 | 1450 | 0.55 |

39 | 50-32-250 | 12.5 | 3.5 | 80 | 2900 | 11 |

40 | 50-32-250 | 6.3 | 1.8 | 20 | 1450 | 2.2 |

41 | 50-32-250A | 11.7 | 3.3 | 70 | 2900 | 11 |

42 | 50-32-250A | 5.9 | 1.6 | 17.5 | 1450 | 1.5 |

43 | 50-32-250B | 11 | 3.1 | 62 | 2900 | 7.5 |

44 | 50-32-250B | 5.5 | 1.5 | 15.5 | 1450 | 1.5 |

45 | 65-50-125 | 25 | 6.9 | 20 | 2900 | 3 |

46 | 65-50-125 | 12.5 | 3.5 | 5 | 1450 | 0.55 |

47 | 65-50-125A | 22.7 | 6.3 | 16.5 | 2900 | 2.2 |

48 | 65-50-125A | 11.3 | 3.1 | 4.1 | 1450 | 0.55 |

49 | 65-50-125B | 20 | 5.6 | 13 | 2900 | 1.5 |

50 | 65-50-125B | 10 | 2.8 | 3.2 | 1450 | 0.55 |

51 | 65-50-160 | 25 | 6.9 | 32 | 2900 | 5.5 |

52 | 65-50-160 | 12.5 | 3.5 | 8 | 1450 | 0.75 |

53 | 65-50-160A | 22.7 | 6.3 | 26.5 | 2900 | 4 |

54 | 65-50-160A | 11.3 | 3.1 | 6.6 | 1450 | 0.55 |

55 | 65-50-160B | 21 | 5.8 | 22.5 | 2900 | 3 |

56 | 65-50-160B | 10.5 | 2.9 | 5.6 | 1450 | 0.55 |

57 | 65-40-200 | 25 | 6.9 | 50 | 2900 | 11 |

58 | 65-40-200 | 12.5 | 3.5 | 12.5 | 1450 | 1.5 |

59 | 65-40-200A | 22.7 | 6.3 | 41 | 2900 | 7.5 |

60 | 65-40-200A | 11.3 | 3.1 | 10.3 | 1450 | 1.1 |

61 | 65-40-200B | 21 | 5.8 | 36 | 2900 | 5.5 |

62 | 65-40-200B | 10.5 | 2.9 | 9 | 1450 | 0.75 |

63 | 65-40-250 | 25 | 6.9 | 80 | 2900 | 15 |

64 | 65-40-250 | 12.5 | 3.5 | 20 | 1450 | 3 |

65 | 65-40-250A | 23.4 | 6.5 | 74.8 | 2900 | 15 |

66 | 65-40-250A | 11.7 | 3.3 | 17.5 | 1450 | 2.2 |

67 | 65-40-250B | 22 | 6.1 | 61.8 | 2900 | 11 |

68 | 65-40-250B | 11 | 3.1 | 15.5 | 1450 | 1.5 |

69 | 65-40-315 | 25 | 6.9 | 125 | 2900 | 30 |

70 | 65-40-315 | 12.5 | 3.5 | 32 | 1450 | 5.5 |

71 | 65-40-315A | 23.4 | 6.5 | 109.5 | 2900 | 22 |

72 | 65-40-315A | 11.7 | 3.3 | 28 | 1450 | 4 |

73 | 65-40-315B | 22 | 6.1 | 96.5 | 2900 | 22 |

74 | 65-40-315B | 11 | 3.1 | 24.1 | 1450 | 3 |

75 | 65-40-315C | 20.5 | 5.7 | 84.1 | 2900 | 18.5 |

76 | 65-40-315C | 10.3 | 2.9 | 21 | 1450 | 3 |

77 | 80-65-125 | 50 | 13.9 | 20 | 2900 | 5.5 |

78 | 80-65-125 | 25 | 6.9 | 5 | 1450 | 0.75 |

79 | 80-65-125A | 45.3 | 12.6 | 16.5 | 2900 | 4 |

80 | 80-65-125A | 22.6 | 6.3 | 4.1 | 1450 | 0.55 |

81 | 80-65-125B | 42 | 11.7 | 14.5 | 2900 | 3 |

82 | 80-65-125B | 21 | 5.8 | 3.6 | 1450 | 0.55 |

83 | 80-65-160 | 50 | 13.9 | 32 | 2900 | 11 |

84 | 80-65-160 | 25 | 6.9 | 8 | 1450 | 1.5 |

85 | 80-65-160A | 45.4 | 12.6 | 26.4 | 2900 | 7.5 |

86 | 80-65-160A | 22.7 | 6.3 | 6.6 | 1450 | 1.1 |

87 | 80-65-160B | 40.5 | 11.3 | 21.5 | 2900 | 5.5 |

88 | 80-65-160B | 20.3 | 5.6 | 5.4 | 1450 | 0.75 |

89 | 80-50-200 | 50 | 13.9 | 50 | 2900 | 15 |

90 | 80-50-200 | 25 | 6.9 | 12.5 | 1450 | 2.2 |

91 | 80-50-200A | 45.3 | 12.6 | 41 | 2900 | 11 |

92 | 80-50-200A | 22.7 | 6.3 | 10.3 | 1450 | 2.2 |

93 | 80-50-200B | 40.5 | 11.3 | 32.5 | 2900 | 7.5 |

94 | 80-50-200B | 20.3 | 5.6 | 8.1 | 1450 | 1.1 |

95 | 80-50-250 | 50 | 13.9 | 80 | 2900 | 30 |

96 | 80-50-250 | 25 | 6.9 | 20 | 1450 | 5.5 |

97 | 80-50-250A | 45.3 | 12.6 | 65.7 | 2900 | 22 |

98 | 80-50-250A | 22.7 | 6.3 | 16.4 | 1450 | 3 |

99 | 80-50-250B | 44 | 12.2 | 62.2 | 2900 | 18.5 |

100 | 80-50-250B | 22 | 6.1 | 15.6 | 1450 | 3 |

101 | 80-50-315 | 50 | 13.9 | 125 | 2900 | 45 |

102 | 80-50-315 | 25 | 6.9 | 32 | 1450 | 7.5 |

103 | 80-50-315A | 45.3 | 12.6 | 102.6 | 2900 | 37 |

104 | 80-50-315A | 22.7 | 6.3 | 25.7 | 1450 | 5.5 |

105 | 80-50-315B | 44 | 12.2 | 97 | 2900 | 30 |

106 | 80-50-315B | 22 | 6.1 | 24.5 | 1450 | 4 |

107 | 80-50-315C | 39 | 10.8 | 77 | 2900 | 22 |

108 | 80-50-315C | 19.5 | 5.4 | 19.5 | 1450 | 3 |

注:1、本产品的过流部件以SUS304材质为准,若要求316或316L材质的,需在单泵基础上另加35%或45%。

2、泵的轴封采用机械密封,采用其它结构的轴封型式,需另外报价。

3、本产品所配电机功率只能满足输送密度类似于清水的化学介质,介质密度增大,所配电机功率应相应加大,否则泵的性能会降低,具体细节请咨询技术部。

企业资料通过认证

企业资料通过认证